TASHIKA

CONTINUOUS CERAMIC FIBER |

Download PDF |

FEATURES

- Superior flexibility

- Does not absorb moisture

- Excellent thermal resistance

- Good thermal insulation properties

- Good electrical insulation properties

DESCRIPTION

TASHIKA continuous ceramic fiber is a Boron-free,Alumina-Silica polycrystal made up of several thousandfine filaments that gives it excellent

flexibility and allow it to be readily transformed into various textile forms

such as thread, rope, woven cloth,

tape and braided sleeve without the aid of any other organic fiber.

Continuous ceramic fiber has properties

such as high tensile strength and modulus, excellent thermal resistance and

outstanding electrical insulation.

It has a wide range of applications in

high temperature operating environment.

TYPICAL PHYSICAL PROPERTIES (Type F)

| 1.Colour |

White |

| 2.Fiberform |

Continuous |

| 3. Filament

diameter |

7 microns |

| 4. Chemical composition |

Al2O3 (72%) + SiO2 (28%) |

| 5.Crystal type |

Gamma Al2O3 |

| 6. Density |

2.9 g/cm3 |

| 7. Tensile

strength |

200 Kgs/mm2 |

| 8. Tensile

modulus |

17,000 Kgs/mm2 |

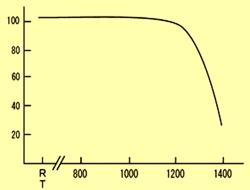

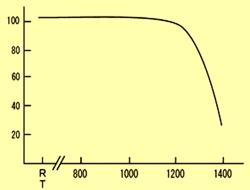

| 9.

Thermal resistance |

Up to 1,250°C as per the |

| tensile

strength retention

percentage Vs increasing temperature

curve shown below: |

|

CERAMIC FIBER YARN

|

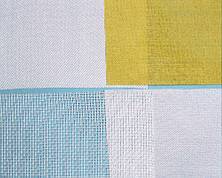

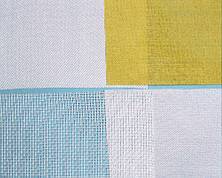

CERAMIC FIBER CLOTH

|

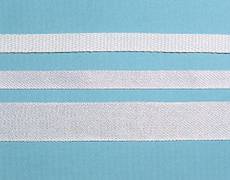

CERAMIC FIBER TAPE

|

CERAMIC FIBER SLEEVE |

Ceramic fiber yarn is available in following three combinations of chemical composition:

- Type G: Alumina (60%) and Silica (40%) for max. application temperature 1,200°C

- Type F: Alumina (72%) and Silica (280%) for max. application temperature 1,250°C

- Type E: Alumina (80%) and Silica (20%) for max. application temperature: 1,300°C

|

| Tensile strength retention (in %) |

|

| Temperature (after 24 hours

heating) |

|

| Back to Top |

APPLICATIONS

- Thermal insultion rings (disks and collars) for diffusion furnaces used in the semi-conductor manufacturing process.

- Furnace linings.

- Heat-Shielding curtain.

- Thermal insulation seals or packing materials.

- Thermal insulation coverings for thermocouple cables and wires.

- Roller covers for tempered glass plate manufacturing.

- Filters for molten aluminium or other metals.

- Spacers for the heat treatment of metal or other materials.

- Abrasive for plastic wetstone.

- Insulators around generator and aircraft/rocket engines.

- Catalyst carries.

- Electrical and thermal insulators for diesel particulate filter systems (DPF).

- Others.

|

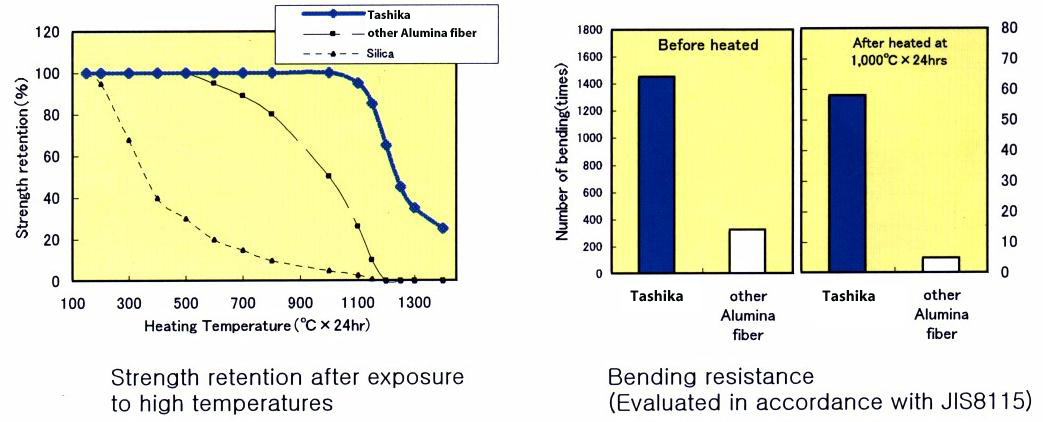

CHARTS

|

| Back to Top |

STANDARD WOVEN FABRIC PRODUCTS

| Type |

Weave |

Yield

of yarn

(tex) |

Yarn

Count(per inch) |

Weight

ig/m2j |

Thickness (mm) |

| Warp |

Fill |

JIS |

ASTM |

| 3025-T

|

Twill |

200 |

30 |

25 |

440 |

0.35 |

0.55 |

| 1111-P |

Plain(mesh) |

620 |

11 |

11 |

550 |

0.68 |

0.87 |

| 0909-P |

Plain(mesh) |

200 |

9 |

9 |

145 |

0.21 |

0.41 |

| 2525-P |

Plain |

67 |

25 |

25 |

135 |

0.15 |

0.21 |

| 2626-P |

Plain |

133 |

26 |

26 |

280 |

0.21 |

0.31 |

| 2220-S |

Satin |

400 |

22 |

20 |

670 |

0.61 |

0.97 |

| 4018-D |

Double Twill |

400 |

40 |

18 |

940 |

0.80 |

1.35 |

| 5537-S |

Satin |

67 |

55 |

37 |

265 |

0.20 |

0.25 |

| 3030-P |

Plain |

33 |

30 |

30 |

80 |

0.08 |

0.10 |

Applied standard to measure thickness (JIS: JIS R3420, ASTM: ASTM D1777).

Standard woven fabric products are all 1m width and 30m/roll.

|

|

STANDARD SEWING THREAD PRODUCTS

| Type |

Yield

(tex) |

FD*

(micron) |

Twist

(T/m) |

Quantity

(g/bobbin) |

Length

(g/bobbin) |

O.D.*

(mm) |

Note |

| T-5760D |

620 |

7 |

125 |

400 |

645 |

1.0 |

Hand sewing |

| CT-2560D |

330 |

7 |

180 |

350 |

1,060 |

0.5 |

Machine sewing |

| CT-5120D |

610 |

7 |

180 |

350 |

573 |

0.8 |

Machine sewing |

|

| Back to Top |

STANDARD ROAP, CODE PRODUCTS

| Type |

Foam |

O.D.*

(mm) |

Twist

(T/m) |

Weight

(g/bobbin) |

Length

(g/bobbin) |

Quantity

(g/bobbin) |

| RP-18 |

Twisted rope |

2 |

100 |

3.8 |

130 |

500 |

| CD-1 |

Braided rope |

1 |

--- |

1.7 |

50 |

85 |

| CD-2 |

Braided rope |

2 |

--- |

3.7 |

50 |

185 |

| CD-3 |

Braided rope |

3 |

--- |

5.4 |

50 |

270 |

*Note :F.D=Filament diameter, O.D=Outside diameter

*Note: Out side diameter gO.Dhmentioned in the tables are just for preliminary knowledge |

STANDARD BLAIDED SLEEVING PRODUCTS

| Type |

Yield of yarn

(tex) |

I.D*

(mm) |

Weight

ig/m j |

Picks

|

Quantity

(m/roll) |

| SV-1-XP |

33 |

03 |

0.7 |

16 |

50 |

| SV-1-SP |

67 |

0.5 |

1.3 |

16 |

50 |

| SV-1 |

133 |

1 |

2.4 |

16 |

50 |

| SV-2 |

200 |

2 |

3.7 |

16 |

50 |

| SV-3 |

3 |

8.3 |

16 |

50 |

| SV-6 |

6 |

12 |

24 |

50 |

| SV-10 |

10 |

20 |

40 |

ab.25 |

| SV-12 |

12 |

24 |

48 |

ab.25 |

| SV-16 |

16 |

38 |

64 |

ab.25 |

| SV-20 |

20 |

44 |

84 |

ab.25 |

| SV-25 |

25 |

70 |

84 |

ab.50 |

| SV-32 |

32 |

108 |

64 |

ab.50 |

| SV-40 |

40 |

91 |

96 |

ab.40 |

| SV-50 |

50 |

124 |

96 |

ab.50 |

| SV-60 |

60 |

182 |

96 |

ab.50 |

| SV-70 |

400 |

70 |

218 |

96 |

ab.50 |

| SV-85 |

85 |

333 |

96 |

ab.40 |

| SV-95 |

95 |

390 |

96 |

ab.30 |

I.D=Inside Diameter

Please contact us if you have special requests or inquiries regarding length or quantity.

Note: Please contact us if you need an item which is not listed in the above product list.

|

| Back to Top |

STANDARD WOVEN TAPE PRODUCTS

| Type |

Weave |

Yield

of yarn

(tex) |

Yarn

Count(per inch) |

Weight

ig/m2j |

Thickness (mm) |

Width

(mm) |

| Warp |

Fill |

JIS |

ASTM |

| TP-25S

|

Twill |

200 |

30 |

22 |

11 |

0.32 |

0.53 |

25 |

| TP-25D

|

Twill |

620 |

48 |

11 |

37 |

1.20 |

1.87 |

25 |

| TP-30S

|

Plain |

200 |

30 |

22 |

13 |

0.32 |

0.45 |

30 |

| TP-40S |

Twill |

400 |

24 |

19 |

29 |

0.50 |

0.83 |

40 |

| TP-50S

|

Plain/Twill |

200 |

30 |

22 |

22 |

0.32 |

0.45/0.53 |

50 |

| TP-70S |

Twill |

200 |

30 |

22 |

30 |

0.32 |

0.53 |

70 |

| TP-100S

|

Twill |

200 |

30 |

22 |

43 |

0.32 |

0.53 |

100 |

Standard woven tape products are all 30m/roll.(except TP-40S,100S)

Applied standard to measure thickness(JIS:JIS R3420,ASTM:ASTM D1777). |

|

| Back to Top |

OTHER PRODUCTS |

|

|

Cut into hoping seizes(0.1-60mm). This is recommended for application of reinforcement.

Colored with inorganic pigment - Red, Blue, and Black Color is sustained even at elevated temperature

- HIGH PURITY CERAMIC FIBER YARN

Note: Please contact us if you have any requests or inquiries regarding the customized products.

|

|

|

|