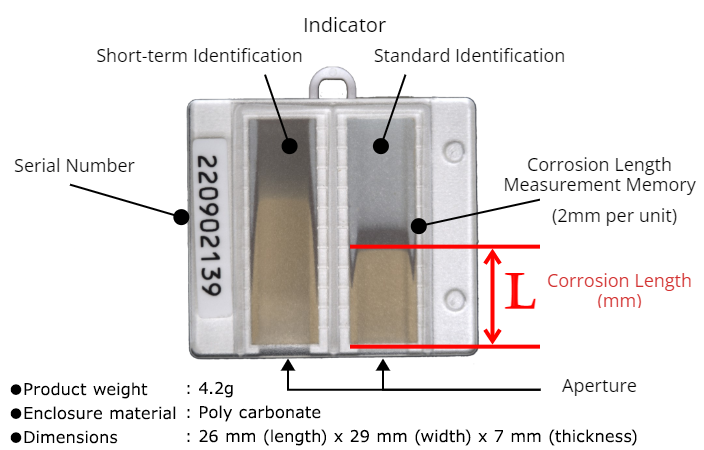

■Capabilities

Visually identify corrosion risks (hydrogen sulfide and sulfur).

Determine

the corrosion category in compliance with ISO 11844-1 based on the

installation period and corrosion length of the Silver Scale™.

Assess the impact of the corrosion category on equipment.

(Reference: ISO 11844-1 standard, ANSI/ISA 71.04-2013 standard)

| Indoor Corrosion Categories |

Impact on equipment |

| IC1 |

- Very low indoor corrosivity |

- Environment sufficiently controlled to ensure that corrosion is not a factor in determining equipment reliability |

| IC2 |

- Low indoor corrosivity |

| IC3 |

- Moderate indoor corrosivity |

- Environment where corrosion may be a factor in determining equipment reliability |

| IC4 |

- High indoor corrosivity |

| IC5 |

- Very high indoor corrosivity |

- Environment where the probability of corrosion attack is high |

| |

Before evaluation |

IC2

(Corrosion Risk: Low) |

IC5

(Corrosion Risk: Very High) |

| Silver Scale |

|

|

|

| Silver Plate (400x) |

|

|

|

LED

Top: 40x

Bottom: 100x |

|

|

|

|

Brightness:4,100lx |

Brightness:3,963lx |

Brightness:2,542lx |

Comparison with existing methods

| |

Silver Scale ™(Visual method) |

Standard methods(ISO11844-1) |

| Summary |

Evaluate and diagnose corrosion risks

based on corrosion length |

Diagnose the corrosion risks based on the

corrosion thickness of the metal plate

measured by an analyzer |

| Advantages |

Visual diagnosis of corrosion risks

Remote diagnosis (identifiable through photos, etc.)

Cost-effective |

Highly accurate analysis due to the usage of an analyzer

Environmental assessment for the corrosion of copper, zinc, and carbon steel |

| Disadvantages |

Environmental assessment only for corrosion of metal (silver) |

Collection and analysis of metal plates can be labor-intensive

Expensive |

|