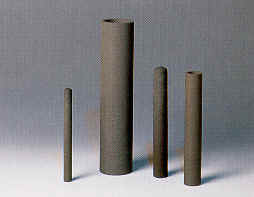

| CERAMIC SINTERED ALUMINA TUBES |

| AluSIK-99 ZA Type C 799 “TEH” |

|

FEATURES:

- High dimensional tolerance

- High heat resistance

- Very high wear resistance

- Chemical corrosion resistance

- Very good thermal conductivity

- High degree of reliability and economy in service

- Very high mechanical & refractory strength, very hard

|

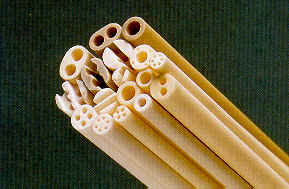

Thermocouple Protection Sheath Thermocouple Protection Sheath |

|

DESCRIPTION:

AluSik –99 ZA

are sintered alumina tubes with excellent temperature stability. They are

popularly used as furnace tubes and protecting and insulating tubes for

high temperature thermocouple assemblies. Because of their high purity and fine grain structure, AluSik –

99 ZA possess high wear resistance high strength, high thermal conductivity and insulating properties.

The Al2O3 content of AluSik –99 ZA is more that 99% making it perfectly suitable

for use in Platinum/ Platinum Rhodium thermocouple as any presence of

silicate would contaminate these thermocouples and reduce their service

life.

AluSick 99 ZA

tubes are available in a variety of sizes with one end closed as

protection tubes or both ends open with 2-hole or 4-holes as insulating

tubes. |

2-hole and 4-hole insulating tubes 2-hole and 4-hole insulating tubes |

PROPERTIES:

Temperature

stability up to 1800°C

AluSik – 99 ZA tubes exhibit stability at temperature as

high as 1,800°C giving it advantage over metal or glass material.

Application temperature also is influenced by the tube geometry, the

diameter, the wall thickness and the method of installation i.e.,

horizontal or vertical.

High chemical resistance

AluSik – 99 ZA has excellent chemical resistivity

and are corrosion resistant against most acids and alkaline. Also, the

stability in neututral or reducing atmosphere is excellent.

High electrical insulation

Due to its very high electrical insulation properties, AluSik –99 ZA is ideal as thermocouple wire insulating tubes and thermocouple protection tubes even in electrically heated furnaces.

Mechanical wear resistance

Due to high mechanical wear resistance AluSik-99 ZA tubes

exhibitslong term stability even when subjected to abrasive environment.

Dimensional flexibility

Various standard sizes are available from 0.5 mm

through 300 mm in diameter. Tubes with non-standard sizes can be offered

in accordance with customer’s specifications and dimensions. |

|

SPECIFICATIONS

| QUALITY |

AluSIK-99 ZA |

| Chem./Phys. Composition |

Sintered alumina |

| Type according to DIN VDE 0335 |

C 799

|

| Chem. Composition Al2O3 |

99.7 %

|

| Structure |

dense

|

| Type of body |

Impervious |

| Bulk density |

3.8 g/cm3

|

| Open porosity |

0 % |

| Limit of application |

1750°C

|

Thermal expansion

20-1000°C

|

8 x 10-6K-1

|

Thermal conductivity 20-100°C

|

25 W/mK

|

Flexural strength

unglazed min.

|

300 N mm-2

|

Mean coefficient of

linear expansion 30~100°C

|

5~7 10-6 K-1

|

| Mean coefficient of

linear expansion 30~600°C

|

7~8 10-6 K-1

|

| Temp. for volume

resistivity 1 MW cm (min.)

|

800°C

|

Thermal shock resistance

|

medium-good |

Spec. electric

resistance at RT

|

1014 cm cm |

600°C

|

108

|

| Maximum

production length for tubes

|

3000

mm

|

Tolerance For Protection Tubes as per DIN 43723

| VDE 0335 Type |

Outer - f (d1) |

Inner - f(d2) |

Length(L±2) |

C 799 |

10 |

6 |

270, 375, 530, 740,1030, 1430, 2030

|

| 15 |

10 |

| 24 |

18 |

|

|

|

SILICON

CARBIDE TUBES

| CarSik-70 ZA |

CarSik-90ZA |

|

| Nitride bounded Silicon Carbide Porous,

(70% SiC, 24% Si3N4). Features high strength up to temperature of

1,450°C |

Dense, Silicon Carbide with good mechanical

properties, at high temperatures of up to 1,700°C |

|

DIMMENSIONS

(in mm)

| Thermocouple Protection Tubes |

Order No. |

OD X ID |

| R 208 |

8 x 5 |

| R 211 |

12 x 8 |

| R 212 |

15 x 10 |

| R 214 |

20 x 15 |

| R 215 |

24 x 18 |

| Multi-Bore

Insulating Tubes (Round) |

| Bore |

O.D. (mm) |

Bore Dia. (mm) |

| 2 |

4.8 |

1.4 |

| 4 |

3.0 |

0.8 |

| 4 |

3.5 |

1.0 |

| 4 |

5.5 |

1.2 |

| 4 |

8.5 |

1.5 |

| 6 |

4.9 |

0.75 |

| 7 |

4.9 |

1.8 |

| Two

Bore Insulating Tubes (Oval) |

| O.D. (mm) |

I.D. (mm) |

Bore Dia. (mm) |

| 2.5 |

1.5 |

0.7 |

| 4.2 |

2.1 |

0.85 |

| 4.3 |

1.4 |

0.7 |

| 4.5 |

3.1 |

1.7 |

| 2.95 |

2.0 |

0.6 |

|

|